ISB-A-802 Series

Busbar-Mount Programmable Current Sensor

The ISB-A-802 Series current sensors provide wideband, high-accuracy AC and DC current measurement for converters, inverters, battery systems, motor drives, and industrial power electronics. With programmable sensing ranges from ±100 A to ±670 A, the series delivers precise analog feedback for control, protection, and system monitoring.

As the lead-wire version of the ISB-A-800 Series, the ISB-A-802 offers the same electrical performance in a wiring-flexible format suited for applications where direct PCB or busbar mounting is not possible. With 4300 VAC isolation, DC–200 kHz bandwidth, and a fast ~3 µs response, the series integrates easily into high-voltage and high-current environments where remote sensor placement is required.

Key Features

- Programmable sensing range from ±100 A to ±670 A

- Wideband DC–200 kHz operation for fast-switching power systems

- 4300 VAC isolation supporting high-voltage industrial design

- Fast analog response around 3 µs enabling real-time control

- Lead-wire package offering flexible mounting and remote placement

- Compact busbar-mount format simplifying power-module integration

- Ratiometric analog output compatible with ADCs and control ICs

Applications

- DC/DC and AC/DC converter current monitoring

- Battery systems and energy-storage current measurement

- Motor drives, VFDs, and industrial motion control

- Solar inverters and renewable-energy converters

- Welding equipment and high-current power systems

- Real-time current feedback for protection circuits

ISB-100-A-802

± 100 A

20.000 mV/A

≤ 0.6 %

≤ 0.1 %

3 uS

ISB-175-A-802

± 175 A

11.429 mV/A

≤ 0.6 %

≤ 0.1 %

3 uS

ISB-300-A-802

± 300 A

6.667 mV/A

≤ 0.6 %

≤ 0.1 %

3 uS

ISB-425-A-802

± 425 A

4.706 mV/A

≤ 0.6 %

≤ 0.1 %

3 uS

ISB-550-A-802

± 550 A

3.636 mV/A

≤ 2.5 %

≤ 1.0 %

3 uS

ISB-670-A-802

± 670 A

2.985 mV/A

≤ 2.5 %

≤ 1.0 %

3 uS

-

GENERAL DATA

•Ambient Operating Temperature: -40 to +105 °C

•Ambient Storage Temperature: -40 to +105°C

•RMS Voltage for AC Insulation: 4.3 kV

•Creepage Distance: >140 mm

•Clearance Distance: > 140 mm

-

ABSOLUTE MAXIMUMS

•Over-Voltage VDD Protection: +10 V

•Reverse VDD Protection: -10 V

•Output Voltage Max: +10 V

•Output Current Max: +/- 70 mA

•Reverse Output Voltage Max: -0.3 V

•Reverse Output Current Max: -50 mA

NOTES

•All specifications at 25°C.

•Specifications dependent on mechanical attachment.

•Specifications are % full scale.

•Output slope is dependent on Vdd. Specifications above assumes 5Vdd.

•Vref = 50%Vdd +/- 1%

•We recommend mounting the sensors with non-magnetic screws for maximum accuracy. We recommend stainless steel, brass, bronze, copper or aluminum.

•Specifications subject to change without prior notice.

Frequently Asked Questions (FAQs)

Match current range, output slope, bandwidth requirements, isolation needs, and wiring layout for the intended system.

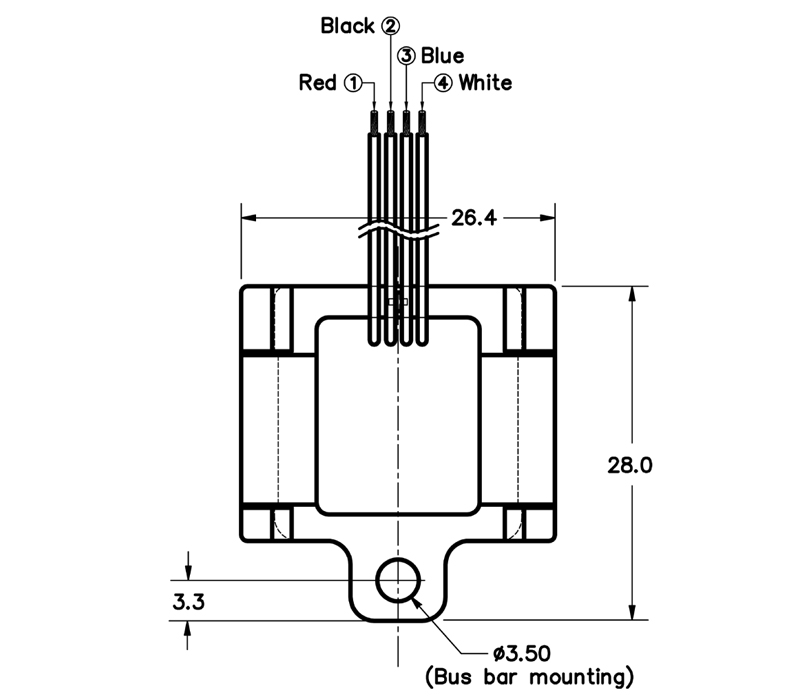

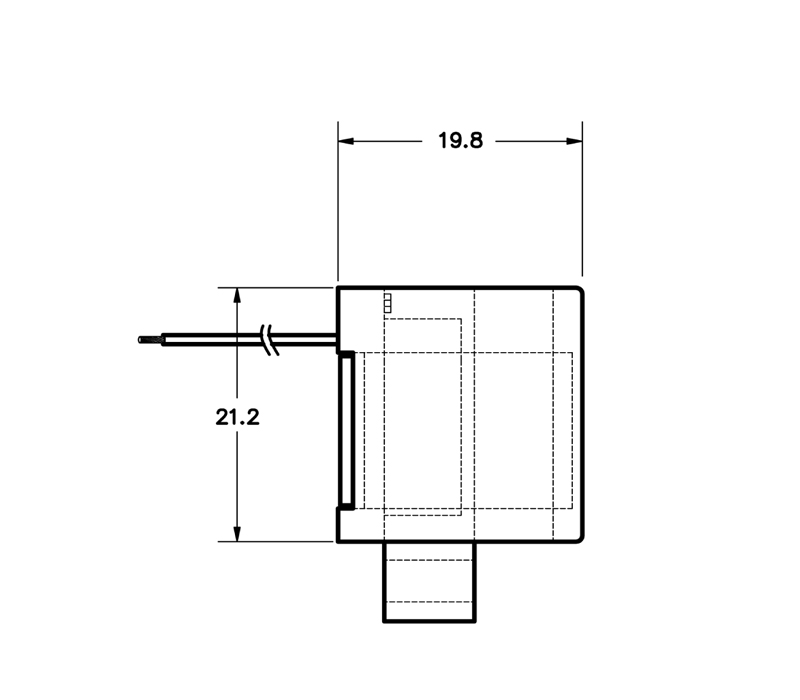

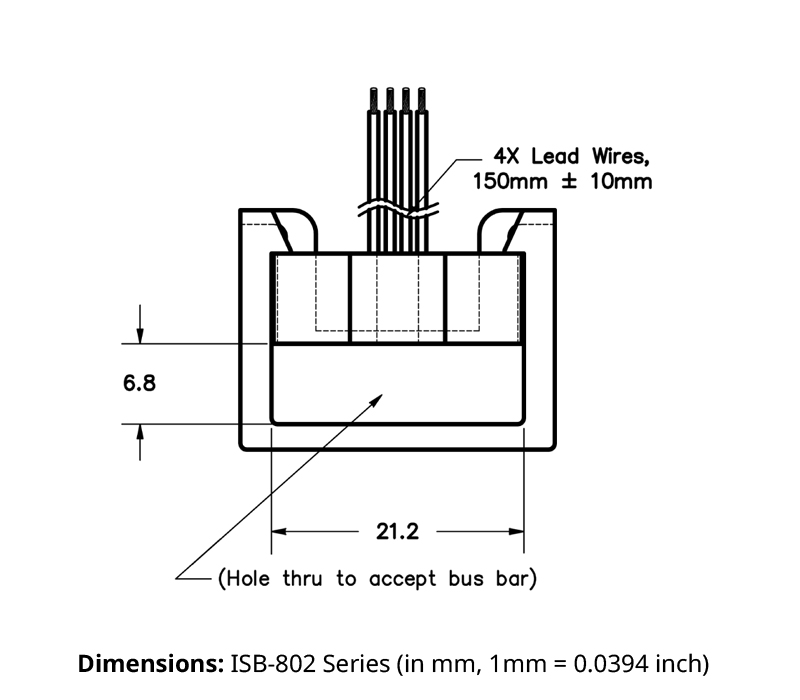

The ISB-A-800 uses a 1.00 mm pitch shrouded header connector (JST BM04B-SRSS-TB with the appropriate mating connector), providing a creepage distance of 8.5 mm. In contrast, the ISB-A-802 is supplied with stranded #22 AWG UL3239-rated lead wires, rated for 3 kV. The standard 150 mm lead length significantly increases the creepage distance to 158.5 mm, with custom lead lengths available upon request.

Variants measure currents from ±100 A to ±670 A, making the series suitable for a wide range of industrial and power-conversion applications.

Yes — the DC–200 kHz bandwidth supports DC, low-frequency AC, switching waveforms, and high-speed transient detection.

It ensures safe separation between high-voltage power paths and low-voltage control electronics, critical for converters, inverters, and battery packs.

A ratiometric analog voltage proportional to sensed current. The slope depends on the variant (e.g., 20 mV/A or 6.67 mV/A).

In systems requiring remote placement of the sensor — such as inside power cabinets, harnesses, or areas with mechanical constraints.

Yes — the ~3 µs response allows fast overcurrent detection and stable control-loop feedback.

The device operates from a regulated 5 V ±0.5 V supply for consistent analog output.

Secure placement with non-magnetic hardware is recommended to prevent magnetic distortion. We recommend mounting the sensors with non-magnetic screws for maximum accuracy - materials such as stainless steel, brass, bronze, copper or aluminum.

Here is the Spice data file for ISB-A-802 Series

Download

Here is the 3D file for ISB-A-802 Series

Download